Product Description

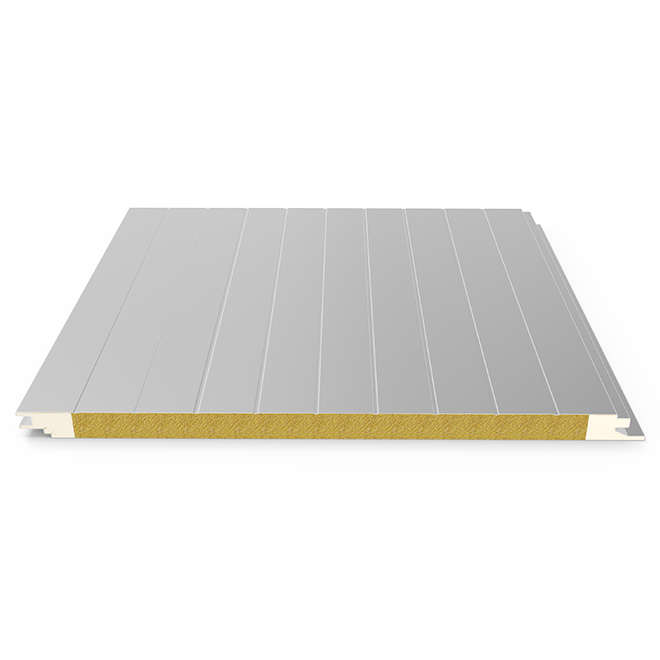

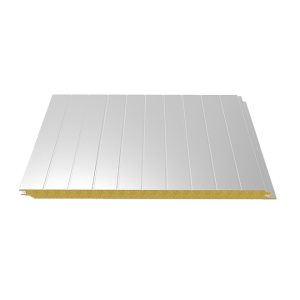

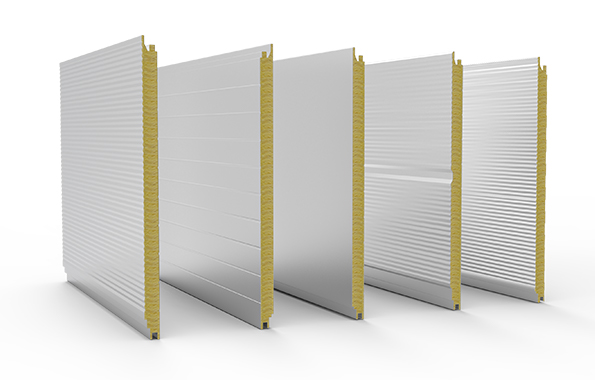

The Fireproof Rock Mineral Wool Sandwich Panel with PU Edge Sealing features an advanced composite construction for superior fire resistance. It comprises a rock wool insulation core sealed between galvanized steel facings, with a polyurethane edge seal for added structural integrity.

Made from naturally flame-resistant rock wool, the Fireproof Rock Mineral Wool Sandwich Panel with Edge Sealing offers optimal safety. The panel’s staggered wool core and polyurethane-sealed edges form a rigid, non-combustible composite rated to slow the spread of fire.

The rock mineral wool sandwich panel is ideal for a variety of building applications. Their rigid, load-bearing design supports heavy usage in factory structures, activity rooms, roofs, walls, clean rooms and partitions while blocking heat, cold and noise transfer through robust insulation properties.

Product Highlights

Fire Safety

Cost Saving & Durability

Sound Insulation

Fast Construction

Long Lifetime

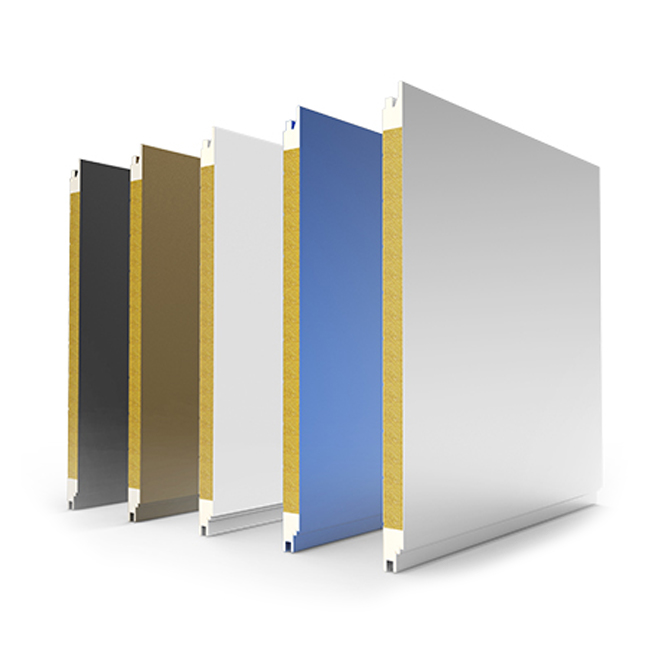

Various Color Choice

Product Parameters

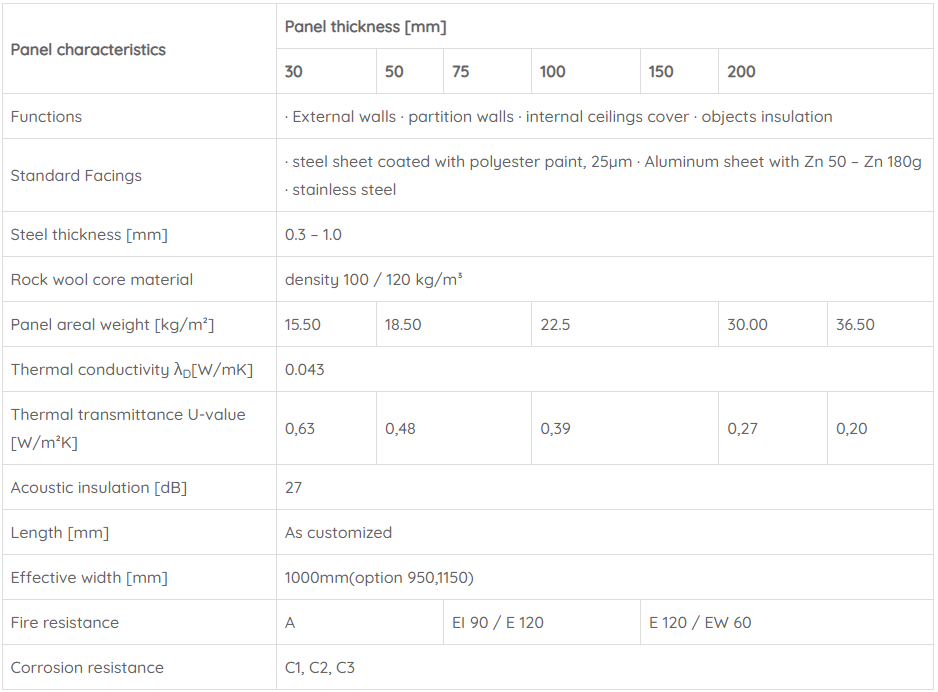

| Panel characteristics | Panel thickness [mm] | |||||||

| 30 | 50 | 75 | 100 | 150 | 200 | |||

| Functions | · External walls · partition walls · internal ceilings cover · objects insulation | |||||||

| Standard Facings | · steel sheet coated with polyester paint, 25µm · Aluminum sheet with Zn 50 – Zn 180g · stainless steel | |||||||

| Steel thickness [mm] | 0.3 – 1.0 | |||||||

| Rock wool core material | density 100 / 120 kg/m³ | |||||||

| Panel areal weight [kg/m²] | 15.50 | 18.50 | 22.5 | 30.00 | 36.50 | |||

| Thermal conductivity λD[W/mK] | 0.043 | |||||||

| Thermal transmittance U-value [W/m²K] | 0,63 | 0,48 | 0,39 | 0,27 | 0,20 | |||

| Acoustic insulation [dB] | 27 | |||||||

| Length [mm] | As customized | |||||||

| Effective width [mm] | 1000mm(option 950,1150) | |||||||

| Fire resistance | A | EI 90 / E 120 | E 120 / EW 60 | |||||

| Corrosion resistance | C1, C2, C3 | |||||||

Application Case

Sandwich panels find extensive use in various applications, serving as exterior and interior partition walls. They can be installed vertically or horizontally on single-span or multi-span structures, providing a visually appealing wall or facade due to their hidden seams. These panels are particularly suitable for the following applications: Industrial buildings, Warehouses and logistic centers, Commercial buildings and offices, Food industry facilities, Agricultural structures, Sports halls.

Assembly Guide

- Prior to installation, proper construction preparation must be carried out, including arranging personnel and ensuring availability of materials. All necessary preparations should be completed.

- Before installing the wall panels, it is essential to check the verticality and levelness of the metope purlin installation to ensure that the wall frame columns meet the required standards.

- For the installation of polyurethane wall panels, begin by attaching the bottom water retaining plate and the water-blocking board at the bottom of the window. Secure the water retaining plate to the wall frame beam using self-tapping screws.

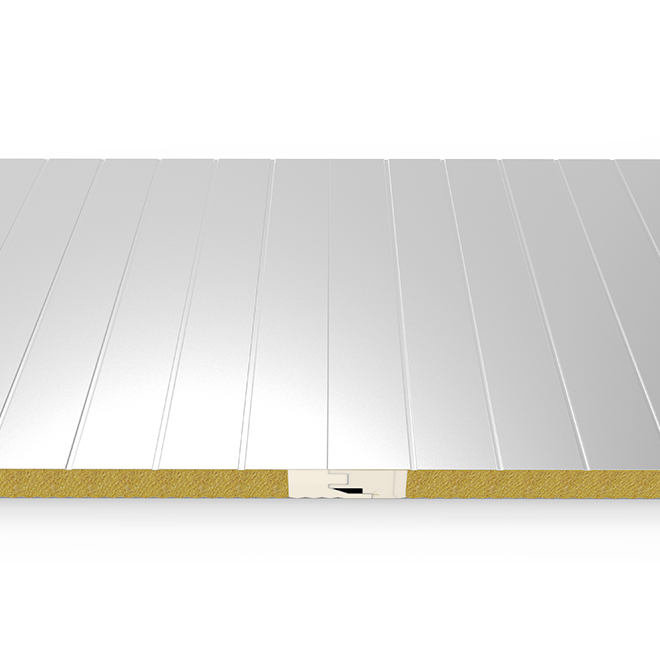

- To connect the polyurethane wall panels with the ground, follow these steps: For lateral connections: Fix one end of the polyurethane sandwich panel to the ground using a round hole and a steel frame. Connect the two panels by overlapping the edges, and if any cracks occur, use insulation material to fill them. For vertical connections: Utilize dedicated buttons with concave grooves to securely fasten the panels together, ensuring there is no gap between them.

EN

EN SA

SA TH

TH ID

ID VN

VN