Product Description

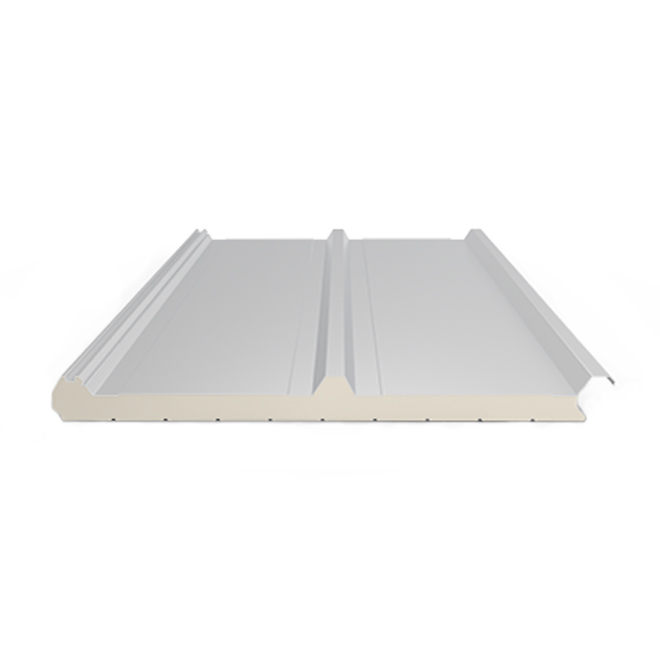

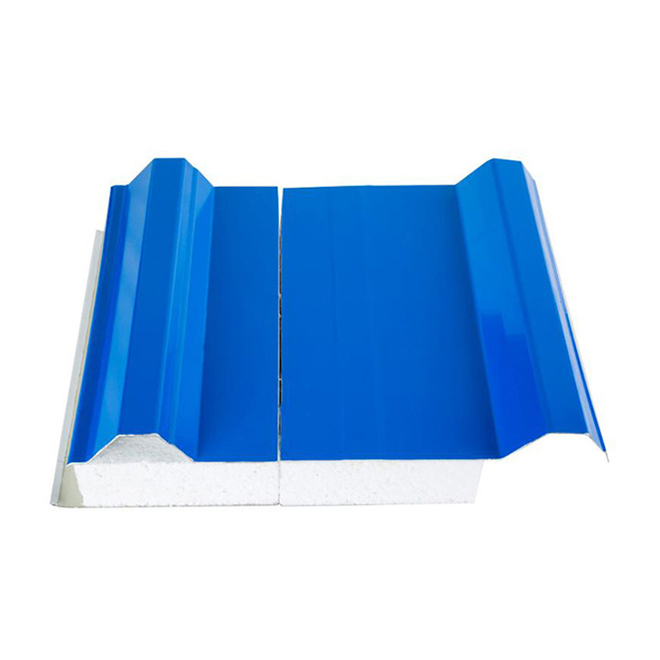

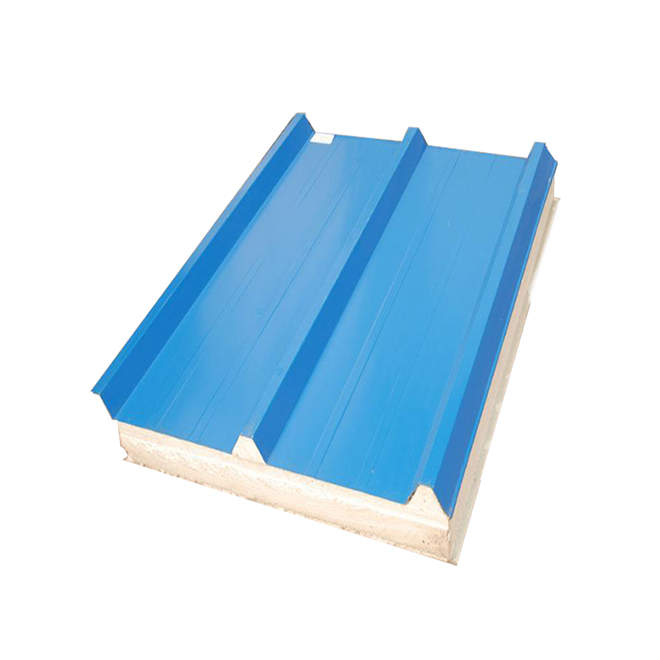

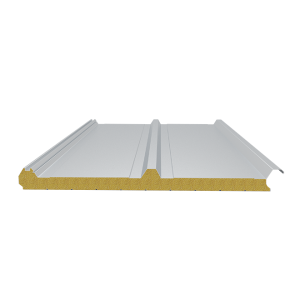

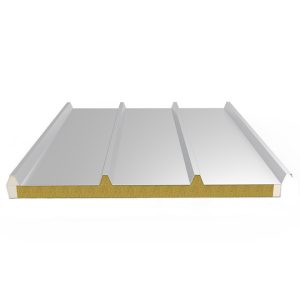

The 75mm 3-Rib EPS Insulated Sandwich Roof Panel is a high-performance roofing solution designed to provide exceptional thermal insulation and durability. Its core material, made of expanded polystyrene foam, ensures excellent insulation properties, effectively reducing heat transfer and enhancing energy efficiency. The 3-rib design of the panel adds structural integrity, making it sturdy and capable of withstanding various weather conditions.

Ideal for a wide range of applications, including residential, commercial, and industrial buildings, this roof panel offers reliable protection and insulation, ensuring comfortable indoor environments while reducing energy consumption and costs.

Product Highlights

- Exceptional thermal insulation for energy efficiency.

- Lightweight construction for easy handling and installation.

- Durable design with 3-rib structure for added strength.

- Effective sound insulation for a quiet indoor environment.

- Resistant to moisture, mold, and pests for a healthy living or working space.

- Versatile application in residential, commercial, and industrial buildings.

- Cost-effective solution for long-lasting performance and reduced energy consumption.

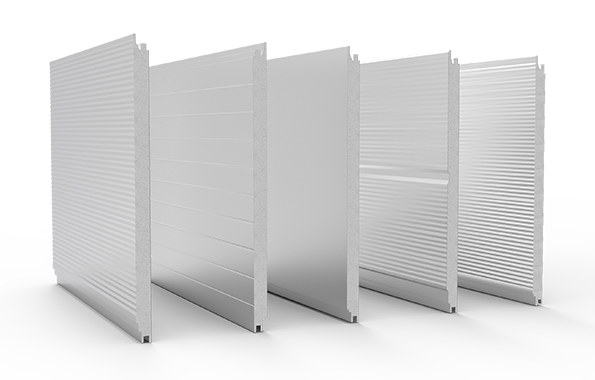

Various Color Choice

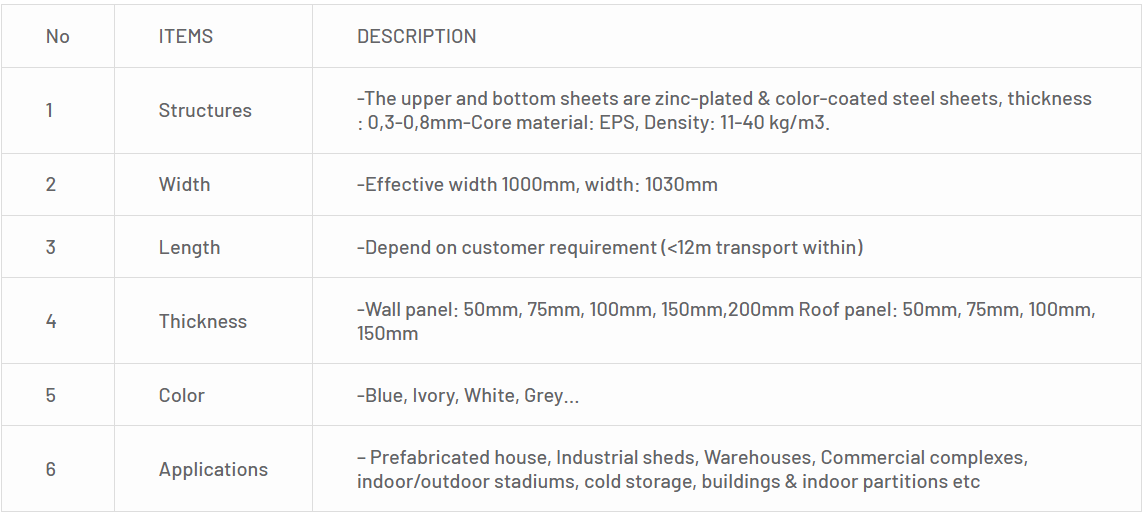

Product Parameters

| No | ITEMS | DESCRIPTION |

| 1 | Structures | -The upper and bottom sheets are zinc-plated & color-coated steel sheets, thickness : 0,3-0,8mm-Core material: EPS, Density: 11-40 kg/m3. |

| 2 | Width | -Effective width 1000mm, width: 1030mm |

| 3 | Length | -Depend on customer requirement (<12m transport within) |

| 4 | Thickness | -Wall panel: 50mm, 75mm, 100mm, 150mm,200mm Roof panel: 50mm, 75mm, 100mm, 150mm |

| 5 | Color | -Blue, Ivory, White, Grey… |

| 6 | Applications | – Prefabricated house, Industrial sheds, Warehouses, Commercial complexes, indoor/outdoor stadiums, cold storage, buildings & indoor partitions etc |

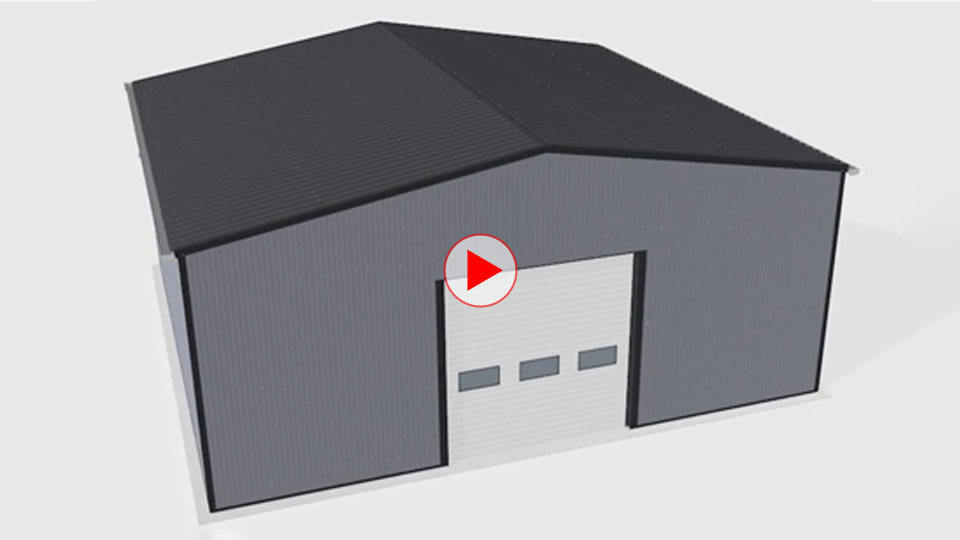

Application Case

Sandwich panels find extensive use in various applications, serving as exterior and interior partition walls. They can be installed vertically or horizontally on single-span or multi-span structures, providing a visually appealing wall or facade due to their hidden seams. These panels are particularly suitable for the following applications: Industrial buildings, Warehouses and logistic centers, Commercial buildings and offices, Food industry facilities, Agricultural structures, Sports halls.

Assembly Guide

- Prior to installation, proper construction preparation must be carried out, including arranging personnel and ensuring availability of materials. All necessary preparations should be completed.

- Before installing the wall panels, it is essential to check the verticality and levelness of the metope purlin installation to ensure that the wall frame columns meet the required standards.

- For the installation of polyurethane wall panels, begin by attaching the bottom water retaining plate and the water-blocking board at the bottom of the window. Secure the water retaining plate to the wall frame beam using self-tapping screws.

- To connect the polyurethane wall panels with the ground, follow these steps: For lateral connections: Fix one end of the polyurethane sandwich panel to the ground using a round hole and a steel frame. Connect the two panels by overlapping the edges, and if any cracks occur, use insulation material to fill them. For vertical connections: Utilize dedicated buttons with concave grooves to securely fasten the panels together, ensuring there is no gap between them.

EN

EN SA

SA TH

TH ID

ID VN

VN