Project Name: Biopharmaceutical Industrial Park

Product Specification: 90mm Polyurethane Sealing Rock Wool Sandwich Panel

Pioneering Resilient Building Solutions for the Coastal Biopharmaceutical Industry

As China’s manufacturing sector accelerates toward higher-end, intelligent, and green development, the biopharmaceutical industry—one of the country’s strategic emerging sectors—is undergoing a rapid transformation. From traditional workshop-style production to digital, automated, and GMP-compliant facilities, the sector demands buildings with higher requirements for durability, cleanliness, energy efficiency, and environmental adaptability.

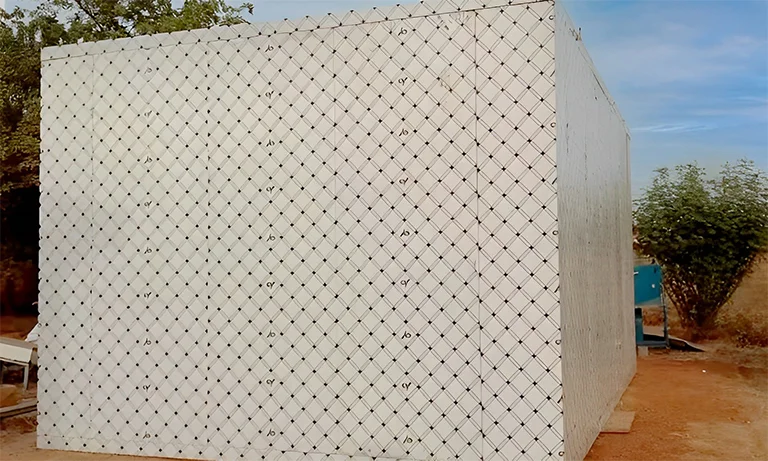

In this trend of industrial upgrading, BRD once again delivers a benchmark project. At the Nantong Tongzhou Bay Biopharmaceutical Industrial Park—an emerging coastal hub integrating R&D, formulation production, cold-chain logistics, and smart manufacturing—BRD provided a tailored external wall system using 0.8mm self-cleaning PVDF-coated high-durability Zinc-Aluminum-Magnesium steel (150g), 0.6mm inner steel sheets, and 90mm PU-sealed Rock Wool Sandwich Wall Panels.

The project demonstrates how advanced building materials can empower the biopharmaceutical sector to achieve “high-standard facilities + long-term durability + energy-efficient operation.”

1. Engineering Excellence Behind a High-Spec Biopharma Park

Biopharmaceutical facilities often face multiple challenges: coastal humidity, salt-laden air, strict temperature control, and long-term operational stability. BRD’s integrated wall system addresses these needs through a “materials upgrade + structural innovation + environmental adaptation” approach.

Superior Fire Safety & Moisture Resistance

The PU-sealed rock wool core combines the fire resistance of mineral wool with the waterproof barrier of polyurethane.

A-level fire safety meets high-standard biosafety construction requirements

PU edge sealing with 99% closed-cell rate completely blocks moisture penetration

Prevents rock wool from absorbing water, maintaining long-term insulation performance

This ensures that the building envelope remains stable even under coastal monsoon conditions.

Coastal-Grade Corrosion Resistance & Long-Term Durability

The exterior panel adopts:

0.8mm self-cleaning PVDF coating

High-end Zinc-Aluminum-Magnesium (150g) anti-corrosion layer

This configuration delivers:

Exceptional resistance to salt spray and humid coastal climate

Self-cleaning surface to maintain appearance and reduce maintenance

Longer service life compared with traditional galvanized steel solutions

The system’s corrosion resistance makes it particularly suited for Tongzhou Bay’s marine environment.

Energy Efficiency for Temperature-Sensitive Pharma Production

The 90mm PU-sealed rock wool core achieves:

Ultra-low thermal conductivity 0.023 W/(m·K)

Stable insulation performance for GMP manufacturing zones

“No-condensation” performance even under temperature differentials in cleanrooms and storage facilities

This supports the industry’s demand for precise environmental control.

2.Service Efficiency Behind BRD’s Reliable Delivery

24-Hour Engineering Response

BRD’s technical service team provided:

Load calculations

Detailing & connection optimization

Full system configuration proposals

Cost and performance evaluations

Intelligent Manufacturing for Fast, Reliable Production

At BRD’s automated production base:

Full-spec panel thickness options (30–200mm)

Width range from 500–1120mm

Automated quality monitoring

Delivery cycle shortened to within 15 days for customized orders

Data-driven manufacturing ensures consistency and reduces maintenance costs during future operation.

Conclusion

In modern industrial construction—especially for highly demanding sectors like biopharmaceuticals—the building envelope is more than a functional shell; it is a critical foundation for operational stability, energy efficiency, and long-term asset value.

Through its PU-Sealed Rock Wool Sandwich Wall System with PVDF-coated Zinc-Aluminum-Magnesium panels, BRD provides a solution that delivers zero leakage, extended service life, superior corrosion resistance, and energy-saving performance.

BRD will continue supporting global biopharmaceutical campuses, industrial parks, and high-standard manufacturing facilities with high-performance, future-ready building solutions.

EN

EN SA

SA CN

CN