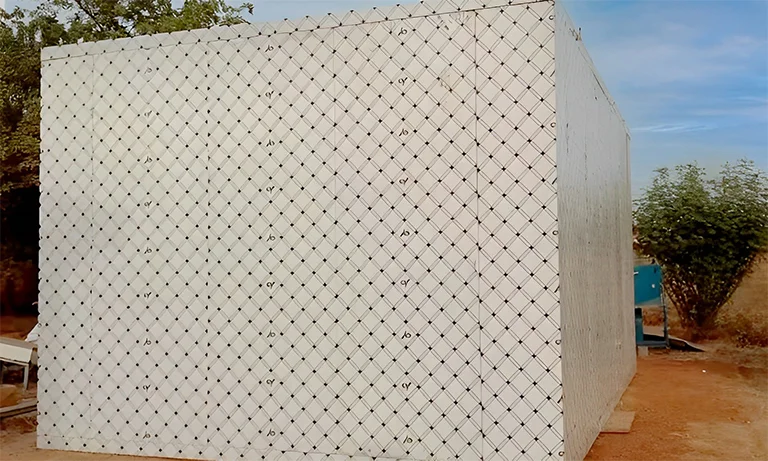

Project Name: Battery Plant

Product Specification: 120mm PU-sealed Rock Wool Sandwich Panels

Building in –30°C: How BRD Solved One of Northern China’s Toughest Construction Challenges

In Guyang County, Baotou City—an area known for –30°C winters, Level-8 winds, and frequent sandstorms—constructing a durable industrial facility is no simple task.

For Aviation Ronghe Battery Industrial Co., Ltd., a key project within the region’s emerging energy-storage industry base, the factory demanded an external wall system that could withstand:

A-level fire protection

Extreme thermal insulation performance

Strong resistance to wind, sand, and corrosion

Long-term durability in harsh, dry, cold climates

Traditional wall materials could not meet these requirements.

BRD provided the answer with its 120mm PU-sealed Rock Wool Sandwich Panels, engineered for lightweight performance, modular construction, and all-climate adaptability—setting a new benchmark for cold-region industrial building envelopes.

Three Core Technologies Redefining Industrial External Walls

- The “Golden Triangle”: Galvanized Steel + Polyurethane Sealing + Rock Wool Core

Independent testing by the China Institute of Building Standard Design & Research shows:

Traditional rock wool boards can have up to 12% water absorption

BRD’s PU edge-sealing technology reduces absorption to below 0.8%, ensuring long-term stability

Outer Alu-Zinc Steel Sheet (AZ150g)

UV-resistant, colorfast for 30 years

No rust for 20 years under natural exposure

Excellent protection against wind erosion and sandstorms

PU Edge-Sealing Technology

99% closed-cell structure fully blocks vapor and moisture

Prevents rock wool from absorbing water, maintaining insulation performance even in –30°C environments

120mm Rock Wool Core

Thermal conductivity maintained at 0.041 ± 0.002 W/m·K in extreme cold

Improves insulation efficiency by up to 50%

Reduces energy consumption significantly for large-scale industrial buildings

- Modular Installation for Extreme-Cold Construction

Customized dimensions with ±1mm precision

All panels pre-fabricated and pre-checked at BRD’s smart factory

Enables rapid assembly—30,000 m² completed in just 30 days

Allows uninterrupted installation even at –20°C, solving the biggest challenge of winter construction

- Fire Safety & Sustainability

A-level non-combustible basalt rock wool

No melting, dripping, or toxic smoke during fire

Meets industrial fire inspection and safety compliance

VOC emissions during manufacturing approach near-zero, supporting green construction standards

Why the Client Chose BRD: A New Benchmark for Cold-Climate Industrial Buildings

BRD’s insulated external wall panel solution not only solved the construction challenges in Inner Mongolia but also:

Reduced future maintenance and operation costs by 30%

Shortened project schedule dramatically through modular assembly

Delivered a wall system that remains stable in high winds, low humidity, and sub-zero temperatures

From food processing plants in Auckland, New Zealand, to battery factories in Ordos, China; from logistics hubs in Kenya to electronics manufacturing parks in Vietnam—

BRD’s PU-sealed rock wool sandwich panels have become the “gold standard” for industrial wall cladding across more than 10,000 global projects.

Choosing BRD Means Choosing Long-Term Value

At Aviation Ronghe Battery’s facility, BRD proved that an industrial wall system is more than the “skin” of a building—it is a strategic asset that strengthens energy efficiency, lowers operational costs, enhances safety, and supports long-term sustainability.

BRD continues to lead the future of industrial building envelopes through:

Lightweight and high-performance wall systems

Intelligent manufacturing

Low-carbon, energy-efficient materials

With professional engineering teams, rapid-response production capacity, and advanced automated equipment, BRD provides technology-driven, durable, and practical external wall solutions for industrial plants, commercial complexes, and public buildings worldwide.

EN

EN SA

SA CN

CN