Product Description

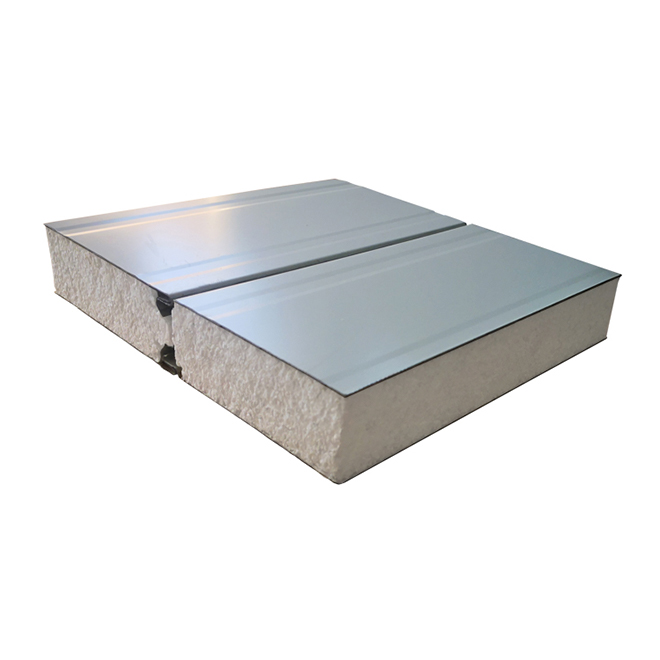

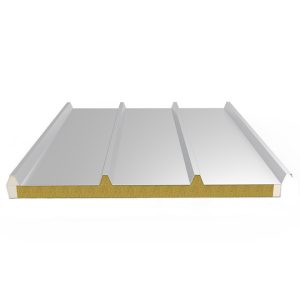

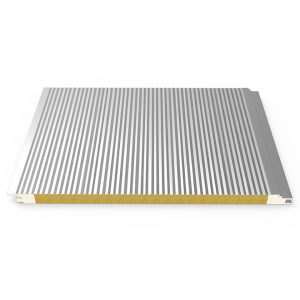

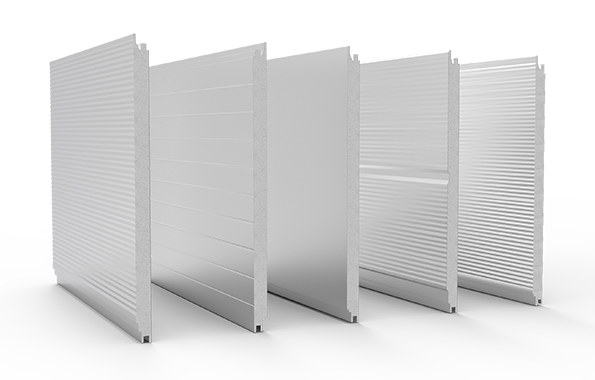

EPS Insulated Sandwich Panels are heat-insulating panels made up of color-coated steel plates as the surface layer and expanded polystyrene foam plastic as the core material, manufactured through a specific production process. These panels are lightweight, offer excellent thermal insulation, and can withstand shear forces, making them a popular choice in construction.

Product Highlights

- Maximizes usable areas with long spans and adaptable layouts.

- Superior insulation for extreme temperature resistance.

- Durable construction lasts 30+ years with minimal maintenance.

- Triple layer wall panel provides waterproof and flame-resistant protection.

- Lightweight handling enables easy staging and installation.

- Cost-effective solution with optimized value through the lifetime.

- Sustainably produced for discerning customers and regulations.

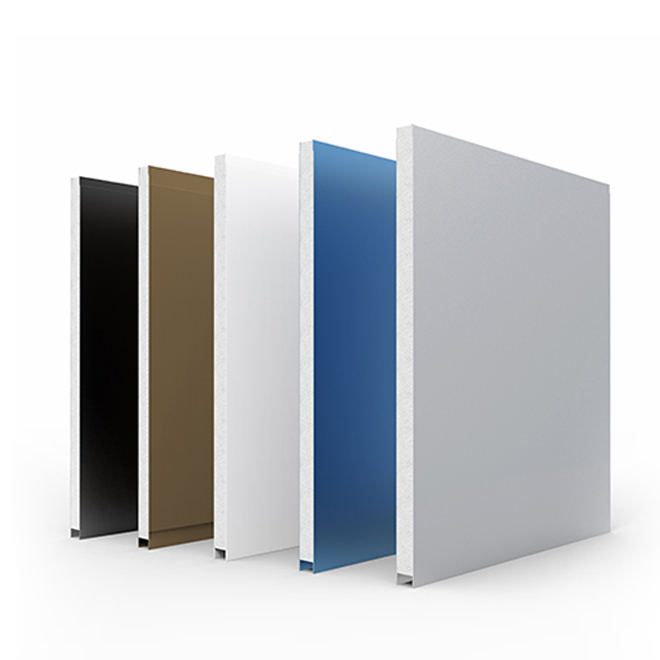

Various Color Choice

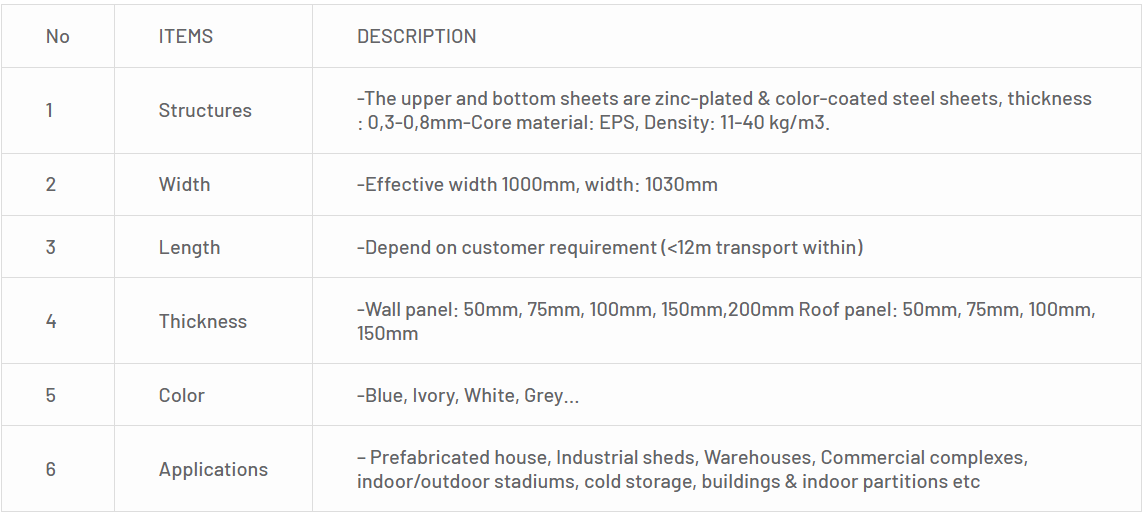

Product Parameters

| No | ITEMS | DESCRIPTION |

| 1 | Structures | -The upper and bottom sheets are zinc-plated & color-coated steel sheets, thickness : 0,3-0,8mm-Core material: EPS, Density: 11-40 kg/m3. |

| 2 | Width | -Effective width 1000mm, width: 1030mm |

| 3 | Length | -Depend on customer requirement (<12m transport within) |

| 4 | Thickness | -Wall panel: 50mm, 75mm, 100mm, 150mm,200mm Roof panel: 50mm, 75mm, 100mm, 150mm |

| 5 | Color | -Blue, Ivory, White, Grey… |

| 6 | Applications | – Prefabricated house, Industrial sheds, Warehouses, Commercial complexes, indoor/outdoor stadiums, cold storage, buildings & indoor partitions etc |

Application Case

Sandwich panels find extensive use in various applications, serving as exterior and interior partition walls. They can be installed vertically or horizontally on single-span or multi-span structures, providing a visually appealing wall or facade due to their hidden seams. These panels are particularly suitable for the following applications: Industrial buildings, Warehouses and logistic centers, Commercial buildings and offices, Food industry facilities, Agricultural structures, Sports halls.

Assembly Guide

- Prior to installation, proper construction preparation must be carried out, including arranging personnel and ensuring availability of materials. All necessary preparations should be completed.

- Before installing the wall panels, it is essential to check the verticality and levelness of the metope purlin installation to ensure that the wall frame columns meet the required standards.

- For the installation of polyurethane wall panels, begin by attaching the bottom water retaining plate and the water-blocking board at the bottom of the window. Secure the water retaining plate to the wall frame beam using self-tapping screws.

- To connect the polyurethane wall panels with the ground, follow these steps: For lateral connections: Fix one end of the polyurethane sandwich panel to the ground using a round hole and a steel frame. Connect the two panels by overlapping the edges, and if any cracks occur, use insulation material to fill them. For vertical connections: Utilize dedicated buttons with concave grooves to securely fasten the panels together, ensuring there is no gap between them.

EN

EN SA

SA TH

TH ID

ID VN

VN