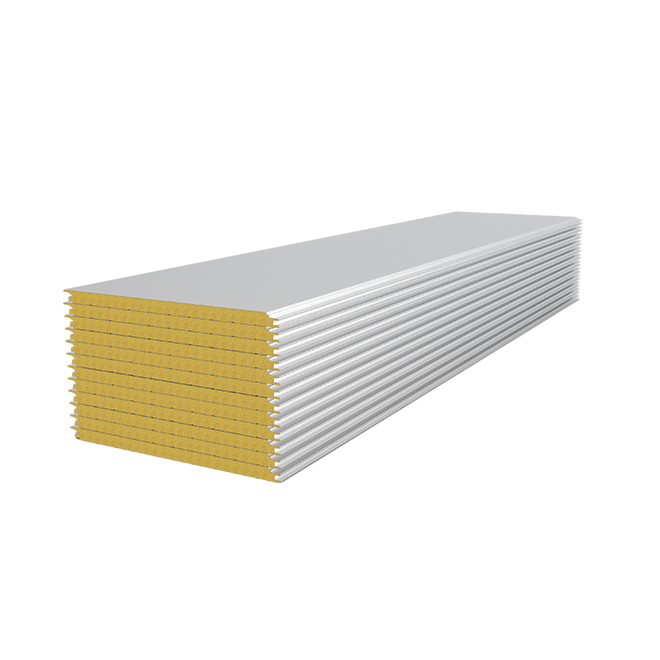

Product Description

Crafted from naturally flame-resistant rock wool, the Fireproof Insulation Rock Wool External Wall Panel offers unmatched safety. Its staggered wool core forms a rigid, non-combustible composite designed to impede fire spread.

This rock mineral wool sandwich wall panel excels across diverse building applications. Its sturdy, load-bearing design thrives under heavy usage in factories, activity rooms, walls, clean rooms, and partitions – robustly insulating against heat, cold, and noise transfer.

Product Highlights

Fire Safety

Cost Saving & Durability

Sound Insulation

Fast Construction

Long Lifetime

Various Color Choice

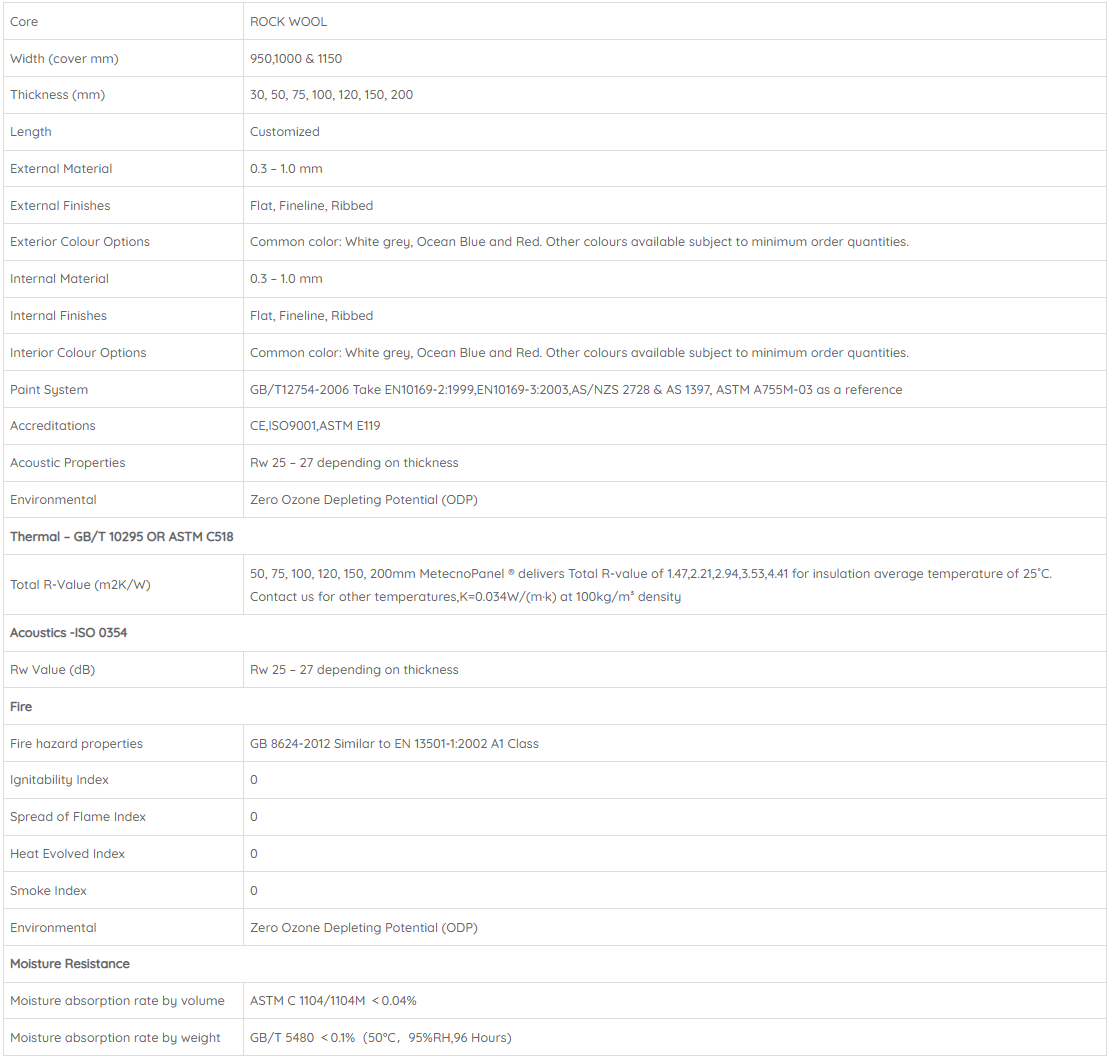

Product Parameters

| Core | ROCK WOOL |

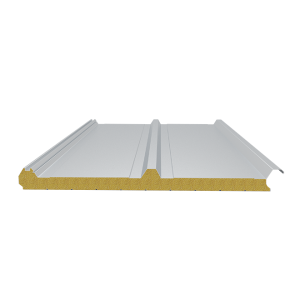

| Width (cover mm) | 950,1000 & 1150 |

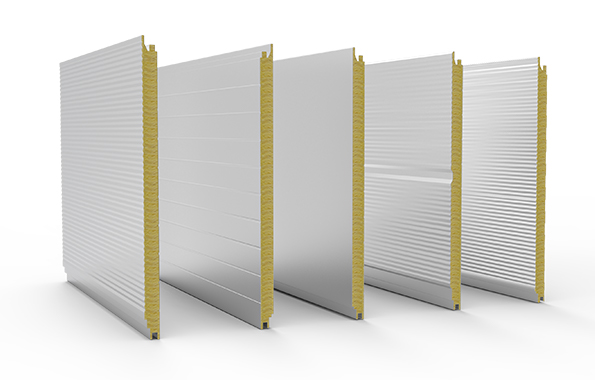

| Thickness (mm) | 30, 50, 75, 100, 120, 150, 200 |

| Length | Customized |

| External Material | 0.3 – 1.0 mm |

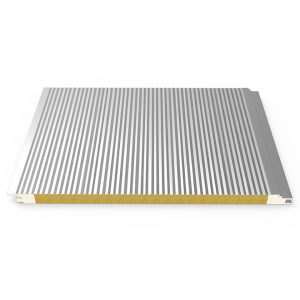

| External Finishes | Flat, Fineline, Ribbed |

| Exterior Colour Options | Common color: White grey, Ocean Blue and Red. Other colours available subject to minimum order quantities. |

| Internal Material | 0.3 – 1.0 mm |

| Internal Finishes | Flat, Fineline, Ribbed |

| Interior Colour Options | Common color: White grey, Ocean Blue and Red. Other colours available subject to minimum order quantities. |

| Paint System | GB/T12754-2006 Take EN10169-2:1999,EN10169-3:2003,AS/NZS 2728 & AS 1397, ASTM A755M-03 as a reference |

| Accreditations | CE,ISO9001,ASTM E119 |

| Acoustic Properties | Rw 25 – 27 depending on thickness |

| Environmental | Zero Ozone Depleting Potential (ODP) |

| Thermal – GB/T 10295 OR ASTM C518 | |

| Total R-Value (m2K/W) | 50, 75, 100, 120, 150, 200mm MetecnoPanel ® delivers Total R-value of 1.47,2.21,2.94,3.53,4.41 for insulation average temperature of 25˚C. Contact us for other temperatures,K=0.034W/(m·k) at 100kg/m³ density |

| Acoustics -ISO 0354 | |

| Rw Value (dB) | Rw 25 – 27 depending on thickness |

| Fire | |

| Fire hazard properties | GB 8624-2012 Similar to EN 13501-1:2002 A1 Class |

| Ignitability Index | 0 |

| Spread of Flame Index | 0 |

| Heat Evolved Index | 0 |

| Smoke Index | 0 |

| Environmental | Zero Ozone Depleting Potential (ODP) |

| Moisture Resistance | |

| Moisture absorption rate by volume | ASTM C 1104/1104M <0.04% |

| Moisture absorption rate by weight | GB/T 5480 <0.1%(50°C,95%RH,96 Hours) |

Application Case

Sandwich panels find extensive use in various applications, serving as exterior and interior partition walls. They can be installed vertically or horizontally on single-span or multi-span structures, providing a visually appealing wall or facade due to their hidden seams. These panels are particularly suitable for the following applications: Industrial buildings, Warehouses and logistic centers, Commercial buildings and offices, Food industry facilities, Agricultural structures, Sports halls.

Assembly Guide

- Prior to installation, proper construction preparation must be carried out, including arranging personnel and ensuring availability of materials. All necessary preparations should be completed.

- Before installing the wall panels, it is essential to check the verticality and levelness of the metope purlin installation to ensure that the wall frame columns meet the required standards.

- For the installation of polyurethane wall panels, begin by attaching the bottom water retaining plate and the water-blocking board at the bottom of the window. Secure the water retaining plate to the wall frame beam using self-tapping screws.

- To connect the polyurethane wall panels with the ground, follow these steps: For lateral connections: Fix one end of the polyurethane sandwich panel to the ground using a round hole and a steel frame. Connect the two panels by overlapping the edges, and if any cracks occur, use insulation material to fill them. For vertical connections: Utilize dedicated buttons with concave grooves to securely fasten the panels together, ensuring there is no gap between them.

EN

EN SA

SA TH

TH ID

ID VN

VN