Product Description

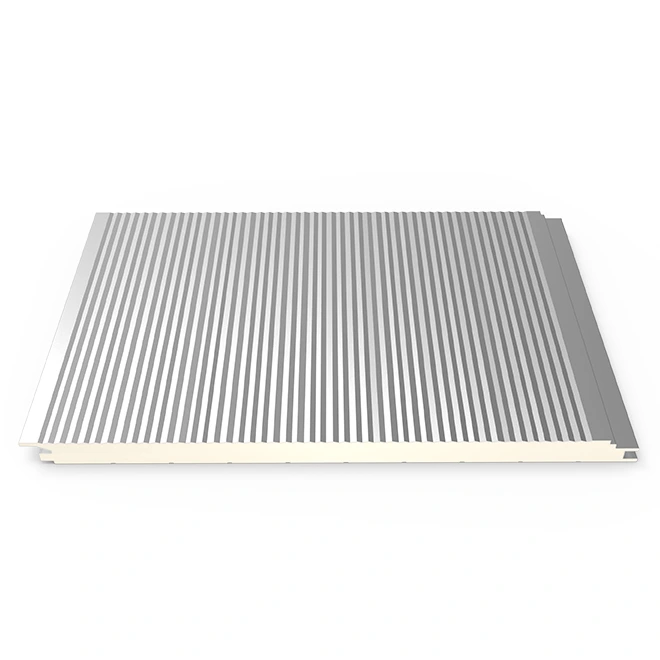

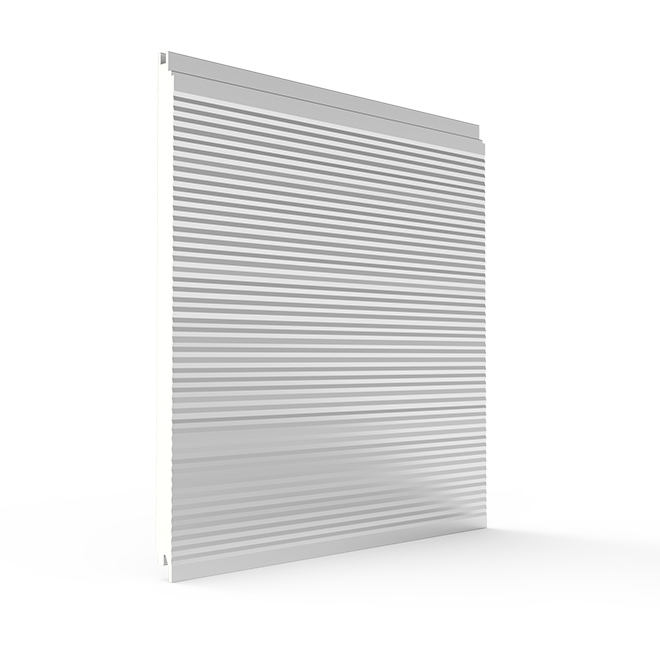

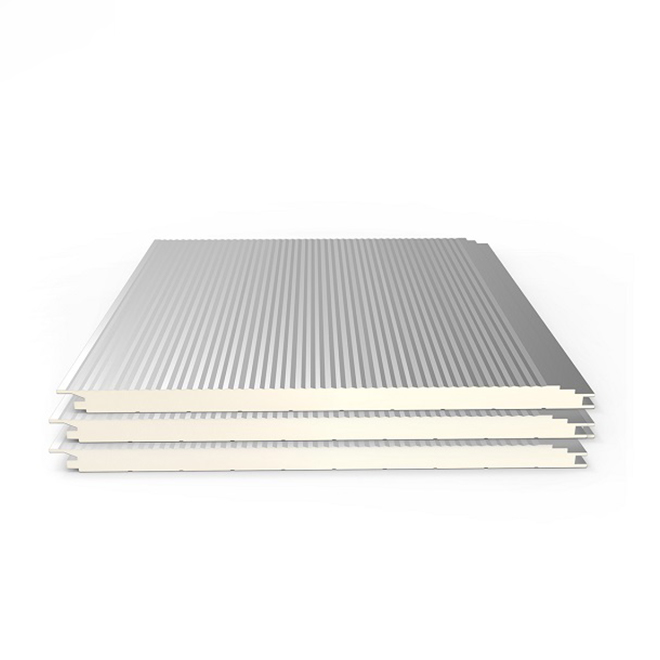

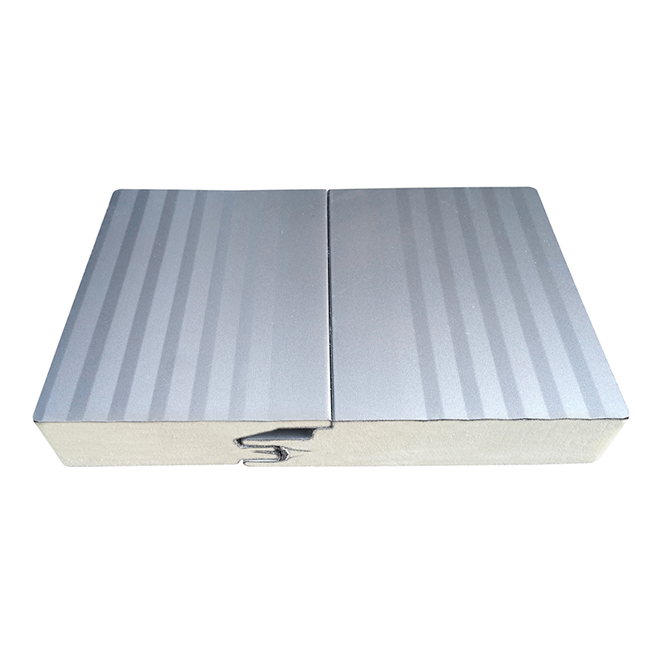

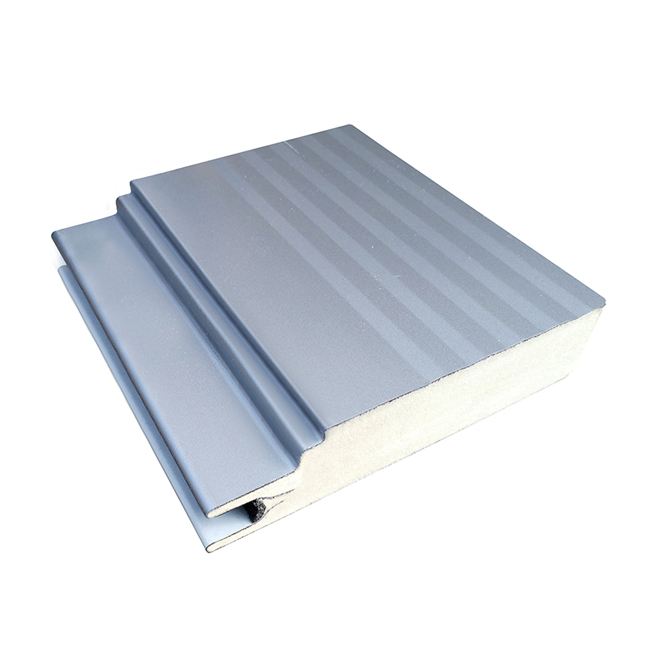

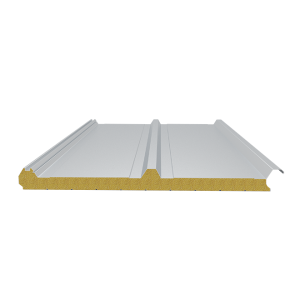

The PU sandwich panels comprise an external and internal galvanized or aluminum sheet bonded to a high-density polyurethane foam core. Polyurethane insulation is the most effective insulant available in the market, with the highest thermal resistance (R-values) at a given thickness and the lowest thermal conductivity. It is widely used in roofs, walls, floors and ceiling cavities, as well as in building exterior applications, in both new and retrofit construction projects. This composite exceeds fire standards and features industry-leading sound absorption properties. Contractors and builders can depend on PU insulated sandwich panels for robust, reliable solutions with unmatched insulating attributes.

Product Highlights

Exceptional Thermal Resistance

With a thermal conductivity of 0.023w/(m.k), our PU panels ensure excellent heat preservation. This saves energy and brings economic benefits.

Durable and Long-Lasting

Designed for decades of maintenance-free use, our panels withstand all weather conditions, providing true value and eliminating replacement costs.

Quick and Easy Installation

Streamlined integration process saves time and labor, reducing project expenses through faster completion.

Sustainable Materials

Our panels are 100% recyclable and manufactured without ozone-depleting substances, promoting green principles from production to disposal.

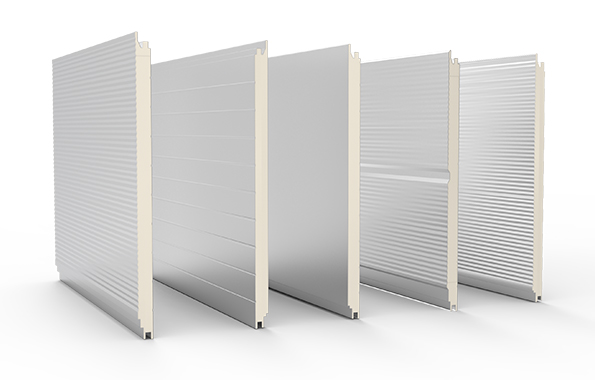

Various Color Choice

Product Parameters

| Panel characteristics | Panel thickness [mm] | |||||

| 50 | 75 | 100 | 150 | 200 | ||

| Functions | · External walls · partition walls · internal ceilings cover · objects insulation | |||||

| Standard Facings | · steel sheet coated with polyester paint, 25µm · steel sheet PLATAL HART PVC (“food safe”) | |||||

| Steel thickness [mm] | 0.3–0.8 | |||||

| PUR foam core density, [kg/m³] | 40 ± 3 kg/m³ | |||||

| Panel areal weight [kg/m²] | 11,10 | 11,80 | 12,60 | 13,40 | 14.1 | |

| Heat conductivity λD [W/mK] | 0,023 | |||||

| Thermal transmittance U-value [W/m²K] | 0,39 | 0,29 | 0,23 | 0,19 | ||

| Acoustic insulation [dB] | 25 | |||||

| Length [mm] | As customized | |||||

| Effective width [mm] | 1000 (option: 1150) | |||||

| Reaction to fire [-] | B-s2, d0; NRO | |||||

| Fire resistance [-] | EI 15 | EI 15 | EI 15 | EI 15 | ||

| Corrosion resistance [-] | C1, C2, C3 | |||||

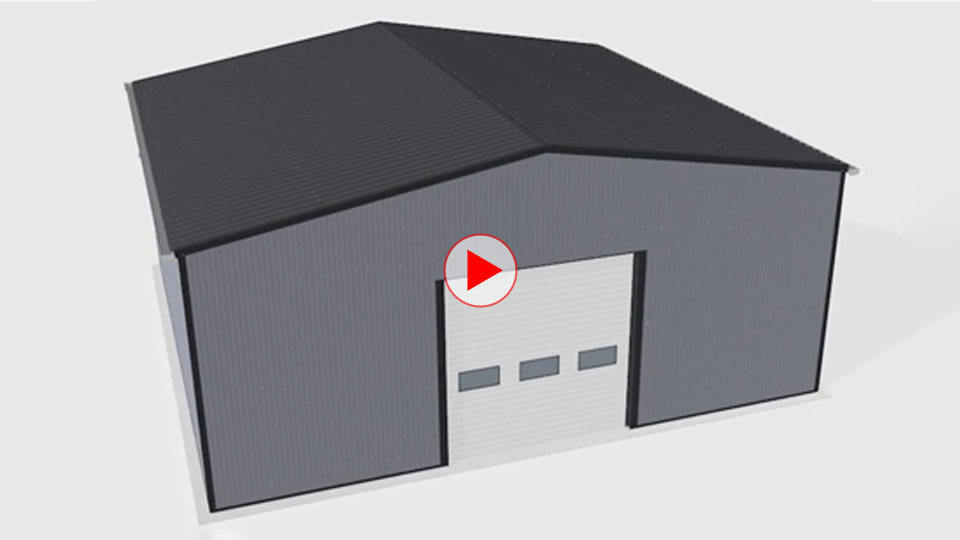

Application Case

Sandwich panels find extensive use in various applications, serving as exterior and interior partition walls. They can be installed vertically or horizontally on single-span or multi-span structures, providing a visually appealing wall or facade due to their hidden seams. These panels are particularly suitable for the following applications: Industrial buildings, Warehouses and logistic centers, Commercial buildings and offices, Food industry facilities, Agricultural structures, Sports halls.

Assembly Guide

- Prior to installation, proper construction preparation must be carried out, including arranging personnel and ensuring availability of materials. All necessary preparations should be completed.

- Before installing the wall panels, it is essential to check the verticality and levelness of the metope purlin installation to ensure that the wall frame columns meet the required standards.

- For the installation of polyurethane wall panels, begin by attaching the bottom water retaining plate and the water-blocking board at the bottom of the window. Secure the water retaining plate to the wall frame beam using self-tapping screws.

- To connect the polyurethane wall panels with the ground, follow these steps: For lateral connections: Fix one end of the polyurethane sandwich panel to the ground using a round hole and a steel frame. Connect the two panels by overlapping the edges, and if any cracks occur, use insulation material to fill them. For vertical connections: Utilize dedicated buttons with concave grooves to securely fasten the panels together, ensuring there is no gap between them.

EN

EN SA

SA TH

TH ID

ID VN

VN