Project Name: Logistics Warehousing, Jiyuan

Product Specification: PU-sealed Rock Wool Sandwich Panel, 40,000 m²

Driven by China’s “Dual Carbon” strategy, the logistics industry is accelerating its transition toward greener and more energy-efficient infrastructure. Following the conclusion of the 2025 National Energy Conservation Promotion Week, the theme of “Improving Energy Efficiency Through Innovation” has resonated strongly across the sector.

As a core component of e-commerce logistics networks, large-scale warehouse buildings are among the most energy-intensive facilities. Wide-span structures, high storage density, and year-round temperature control requirements make energy performance a critical concern.

Project Background: JD Logistics Park, Jiyuan

During the expansion and upgrade of JD Logistics Park in Jiyuan, the project faced three key challenges:

How to reduce HVAC energy consumption during extreme summer and winter temperatures

How to maintain a stable and secure storage environment for high-value goods

How to meet green building standards without extending construction timelines

With a total exterior wall area of 40,000 m², the project required a reliable manufacturer capable of stable supply, fast delivery, and consistent quality. The solution ultimately focused on upgrading the building envelope with high-performance insulation materials.

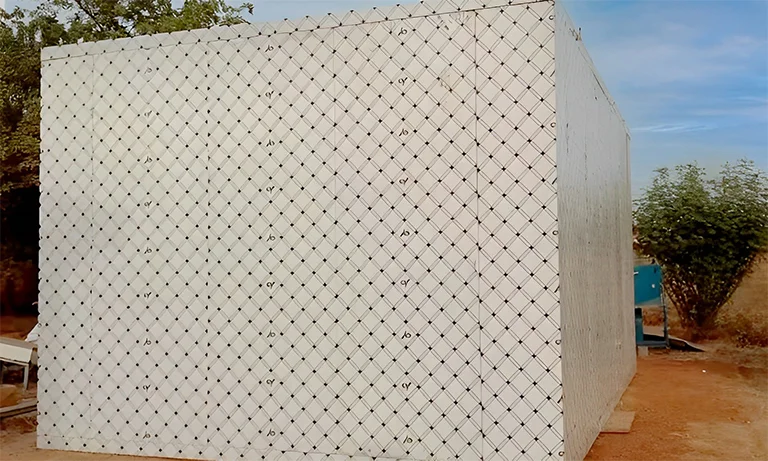

BRD PU-Sealed Rock Wool Sandwich Panels: A Complete Exterior Wall System

With over 20 years of manufacturing experience, BRD provided PU-sealed rock wool sandwich panels designed specifically for modern logistics and industrial buildings. This system integrates thermal insulation, fire resistance, waterproofing, and structural strength into one efficient exterior wall panel solution.

The core advantages of the BRD sandwich panel system include a triple-layer protection structure:

Surface Layer

Double-sided pre-painted steel sheets with excellent corrosion resistance and long-term durability

Insulation Core

High-density rock wool filling, delivering enhanced thermal insulation and sound absorption

PU Sealing System

Rigid polyurethane foam sealed along the panel edges, effectively eliminating thermal bridges and moisture penetration

Key Performance Benefits on Site

- Superior Thermal Insulation, Lower Energy Consumption

With a closed-cell rate of ≥97%, the insulation core forms a highly efficient thermal barrier. On-site data shows that, during summer conditions, warehouse interiors using BRD insulation panels maintained temperatures 5–8°C lower than conventional buildings, reducing air-conditioning energy consumption by approximately 35%.

- A-Class Fire Resistance for Safer Storage

Certified to A-Class non-combustible standards, the rock wool core features a melting point above 1,000°C. In the event of fire exposure, it neither spreads flames nor releases toxic smoke, providing strong protection for stored goods.

- Fast Installation, Shorter Construction Cycle

The panels utilize an interlocking installation system, enabling fast, modular assembly similar to “building blocks.” For this 40,000 m² project, the exterior wall installation period was reduced by around 40%, helping the project stay on schedule.

Conclusion: Building a Greener Logistics Future

At BRD, we believe that green buildings should be the standard, not a luxury. Energy-saving building materials are not just the outer skin of a structure—they are a key driver of sustainable industrial transformation.

The successful application of BRD PU-sealed rock wool sandwich panels at JD Logistics Park in Jiyuan once again demonstrates their outstanding performance in energy efficiency, safety, and long-term value creation. BRD will continue to invest in innovation and R&D, delivering more efficient, environmentally responsible, and intelligent exterior wall and insulation panel solutions for logistics, industrial, and commercial buildings worldwide.

EN

EN SA

SA CN

CN