Project Name: ALTON’s New Eco-Friendly Super Factory

Product Specification: 50mm Polyurethane Sealing Rockwool Panel

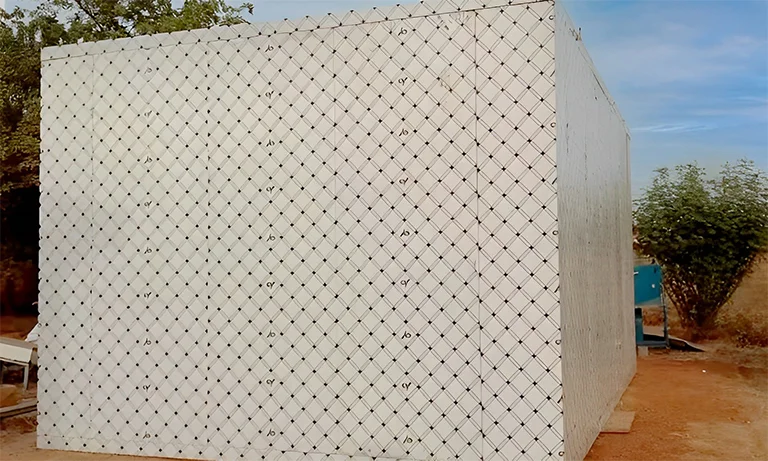

In the construction of the new Super Factory, strict requirements for thermal insulation, fire safety, and long-term durability made traditional materials insufficient for the project’s needs. The facility demanded an exterior system capable of delivering strong protection while maintaining energy efficiency and low maintenance costs. To meet these challenges, BRD was selected to provide its advanced polyurethane edge-sealed rock wool insulated sandwich panels for both the warehouse exterior panel system and wall cladding for ALTON’s New Eco-Friendly Super Factory.

High-Performance Panel System for Extreme Energy Efficiency

BRD’s 50mm PU edge-sealed rock wool sandwich panels combine polyurethane’s high insulation performance with the stability and fire resistance of rock wool. This “dual-core” combination ensures excellent thermal efficiency, reduced energy loss, and stable performance throughout the building’s lifecycle.

Three Core Technologies: Redefining Exterior Wall Panel Performance

- Polyurethane Edge-Sealing Technology

The rigid polyurethane foam used in BRD’s panels delivers:

Ultra-low thermal conductivity

Zero ozone-depleting potential

Exceptional moisture resistance, preventing water vapor penetration into the rock wool core

This edge-sealing process significantly reduces thermal bridging compared with conventional wall panel sandwich systems.

- Rock Wool Fire-Resistant Core

The rock wool core provides:

Up to 2-hour fire rating

Improved acoustic absorption

Stable thermal performance over wide temperature variations

It ensures the building envelope meets strict fire-safety standards for large industrial facilities.

- Concealed Fastening & Tongue-and-Groove Joint System

BRD’s warehouse exterior panels feature:

Hidden fixing for a seamless façade

Faster modular installation with precision-fit joints

Lightweight but strong panel structure, reducing labor time and overall construction cost

This system enhances both the appearance and the airtightness of the exterior enclosure.

Fast Installation, Reduced Energy Costs, Long-Term Value

With their precision-molded sandwich panel design and modular dimensions, BRD panels allow rapid installation across large roof and wall areas. The improved insulation performance helps the Super Factory achieve significant reductions in heating and cooling energy consumption, lowering long-term operating costs.

A Reliable Building Envelope Solution for Modern Industrial Facilities

BRD’s insulated sandwich panel system not only solves the factory’s exterior enclosure challenges but also supports the project’s goals of energy efficiency, safety, and sustainable construction.

BRD has also delivered high-performance sandwich panel systems to several major industrial projects worldwide, including the Antmed Medical Manufacturing Plant and the EVE Lithium Battery Manufacturing Plant in Malaysia. These successful cases demonstrate BRD’s capability in providing reliable wall panel sandwich, warehouse exterior panel, and PU-edge sealed rock wool insulation solutions for demanding environments.

We offer Sandwich Panels, Cold Room Panels, Metal Siding Panel, Garage Doors and more, all available for customization. Contact us to discuss your project needs and get a free quote.

EN

EN SA

SA CN

CN