Product Description

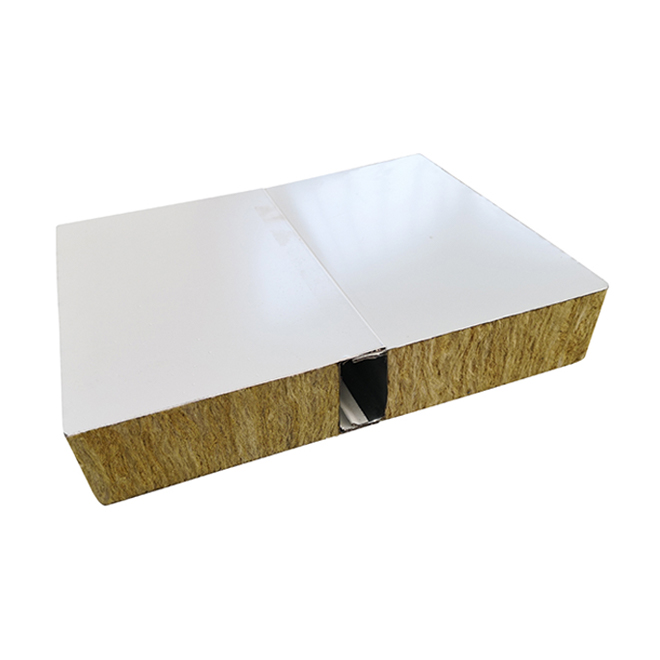

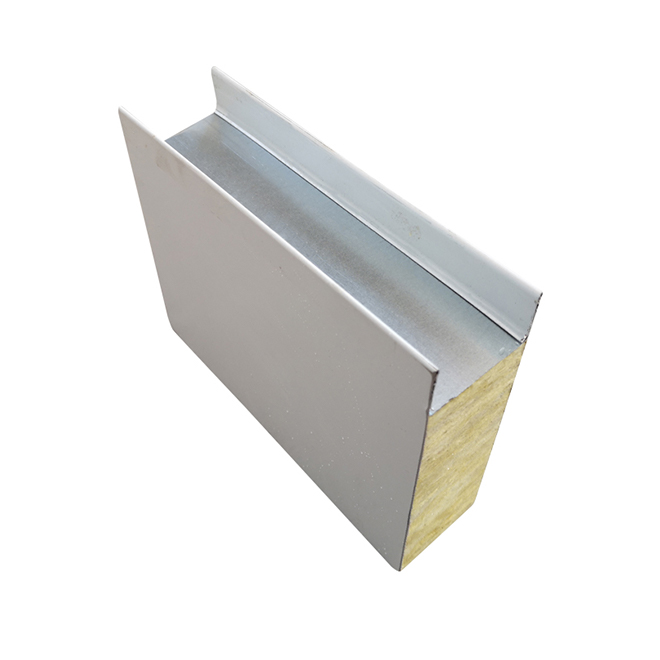

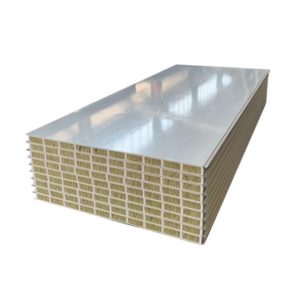

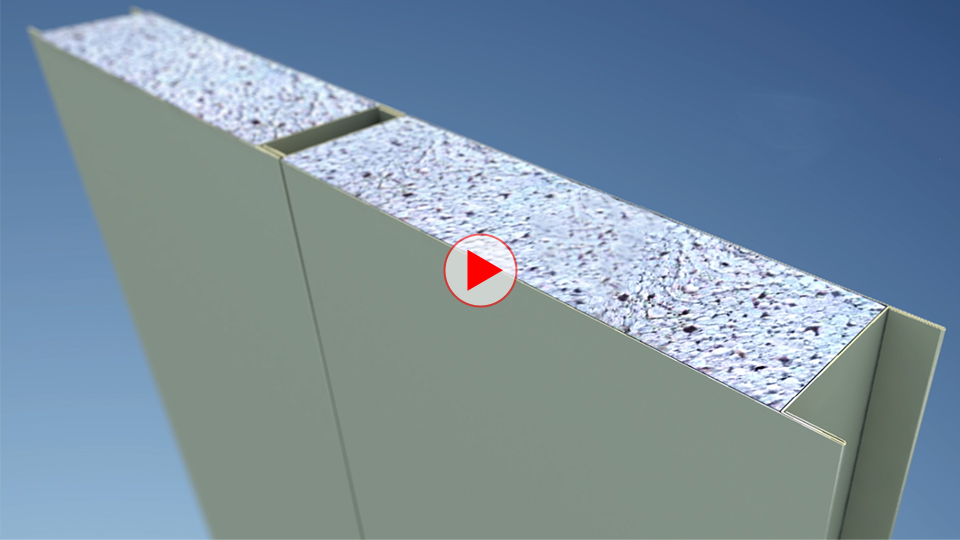

Sandwich clean room panels are an essential component in the construction of clean rooms and controlled environments, providing a reliable and versatile solution for maintaining strict cleanliness and environmental control standards. Their layered construction and modularity make them a popular choice for industries like pharmaceuticals, biotechnology, electronics, and semiconductor manufacturing, among others.

Product Highlights

- Lightweight: Weighing 10-14kg/m, equivalent to 1/30 of a brick wall.

- Thermal insulation: Integrates load bearing, insulation and waterproofing.

- High strength:Can be used as enclosure structures and load-bearing structures with wide applicability for bending and compression resistance.

- Vivid colors: No need for surface decoration. Efficient corrosion prevention with colorful galvanized steel plates without warping or melting.

- Flexible and fast installation: Greatly shorten construction period.

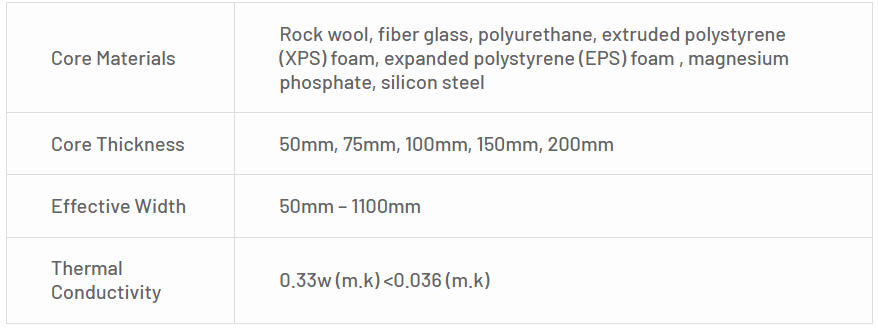

Product Parameters

| Core Materials | Rock wool, fiber glass, polyurethane, extruded polystyrene (XPS) foam, expanded polystyrene (EPS) foam , magnesium phosphate, silicon steel |

| Core Thickness | 50mm, 75mm, 100mm, 150mm, 200mm |

| Effective Width | 50mm – 1100mm |

| Thermal Conductivity | 0.33w (m.k) <0.036 (m.k) |

Application Case

Ideal for industries such as pharmaceuticals, biotechnology, electronics, and healthcare, these panels ensure airtight enclosures, advanced insulation, and customizable options to meet the precise requirements of clean room facilities.

Assembly Guide

EN

EN SA

SA TH

TH ID

ID VN

VN