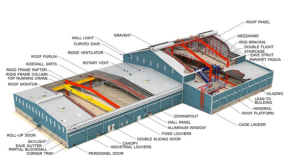

Light steel structure building is a new type of building structure system, which is formed by the main steel framework linking up H-section, Z-section, and U-section steel components, roof and walls using a variety of panels and other components such as windows and doors. Light steel structure building is widely used in warehouses, workshops, large factories, and so on.

Advantages of Steel Structure Building

High Strength-to-Weight Ratio: Steel’s impressive strength-to-weight ratio allows for large, open-span designs with fewer columns. This not only offers greater architectural flexibility but also reduces foundation and transportation costs.

Fast Construction: Steel components are prefabricated off-site, which significantly speeds up on-site assembly. This reduces labor costs and helps you complete projects faster and on schedule.

Versatility and Adaptability: Steel is a highly versatile material that can be molded into various shapes and sizes, making it ideal for everything from warehouses to skyscrapers. Steel structures are also easy to modify or expand as your needs change.

Durability and Sustainability: Steel is durable, resistant to pests and rot, and fire-resistant when properly treated. As a 100% recyclable material, it reduces waste and conserves resources, making it an environmentally friendly choice.

Category | Specification | Description |

Structural Members | Columns, Beams, Trusses | Hot-rolled wide-flange (W-shape) or I-beams are standard. Hollow Structural Sections (HSS) are often used for columns and bracing. |

Steel Grades | ASTM A992, ASTM A36, ASTM A572 Grade 50 | These are common steel grades. A992 is frequently used for wide-flange beams and has a minimum yield strength of 50,000 psi. A36 is a versatile and cost-effective carbon steel with a minimum yield strength of 36,000 psi. |

Connections | Bolted and Welded | Bolted connections use high-strength bolts (e.g., ASTM A325 or A490) and are efficient for assembly. Welded connections (per AWS D1.1 standards) create strong, rigid joints and are often used for critical structural elements. |

Foundations | Concrete Foundation | Steel structures require a sturdy foundation, typically reinforced concrete, to transfer the building’s loads to the ground. Foundation design depends on soil conditions and structural loads. |

Roof and Wall Systems | Metal Panels, Decking | The roof and walls are commonly made with insulated metal panels or steel decking with a concrete topping for composite floors. These materials are chosen for their durability, insulation properties, and quick installation. |

Protective Coatings | Primer and Paint | To prevent corrosion, structural steel is typically shop-applied with a rust-inhibiting primer. A final paint system or galvanization is then applied to provide long-term protection from the elements. |

Why Choose BRD Steel Structure?

Cost-Effective Manufacturing: Our 50,000 m² factory and production line allow us to offer prices 30% lower than the Saudi market. We also help you meet local content requirements for state-owned enterprises and EPC contractors, and we hold all necessary certifications.

Integrated Design Support: Our in-house design institute provides detailed drawings and design optimization, giving you a seamless, worry-free process from initial quote to project completion.

Expert and Reliable Workforce: We have a professional construction team that is familiar with international labor regulations, ensuring smooth project execution.

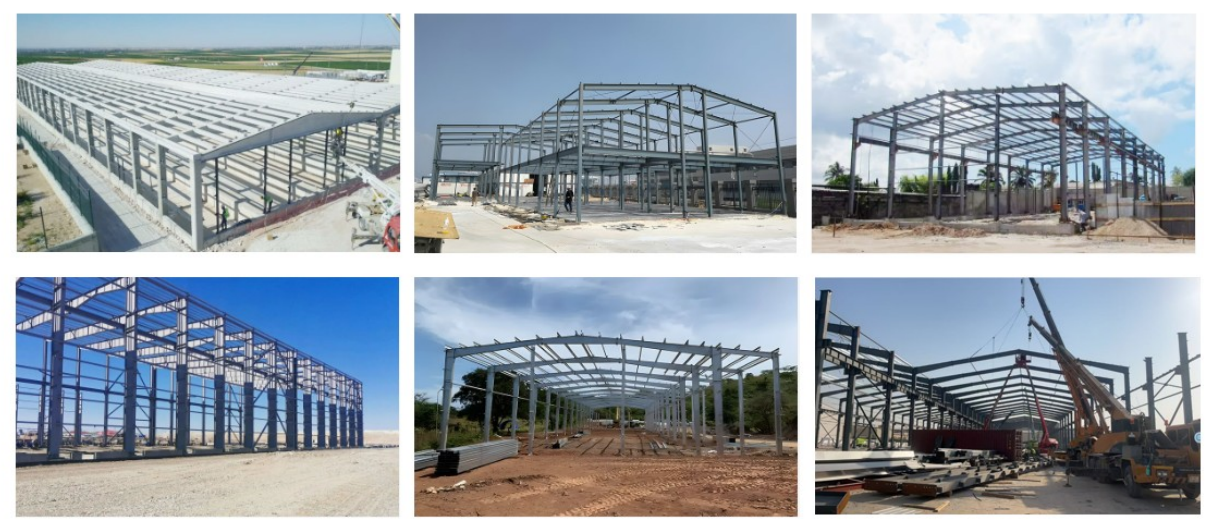

Proven Experience: With 25 years in the industry and 120 completed projects, our track record speaks for itself.

Project Cases

EN

EN SA

SA CN

CN